Concrete Spalling is the breakdown of concrete via natural weathering and/or chemical Reaction that results in sections of cement chipping off the main body – often resulting in fractured compromised concrete.

Effect of Concrete Spalling

As soon as spalling occurs, it should be repaired appropriately, otherwise, it compromises the integrity of the concrete surface and threatens the maximum ability of the component. Moreover, it distorts the aesthetic appearance of the structural member.

A common issue found in old concrete structures is spalling of concrete. Excessive spalling and delamination results in the steel reinforcement to be further exposed to the atmospheric element, where it will corrode even further. This will lead to a reduction of strength as the rebar continues to deteriorate. This leads to a weakened concrete that may not be adequate under loads in bridges, structure etc.

If spalling and continuous corrosion takes place without any monitoring or checks, this can potentially lead to failure of concrete elements. Regular monitoring of concrete and structures of important significance (i.e, hospitals, bridges) is required and remediation should be undertaken if required.

NOTE

Reinforcing steel is used in concrete to increase its tensile strength. As we know, concrete has excellent compressive strength but low tensile strength.

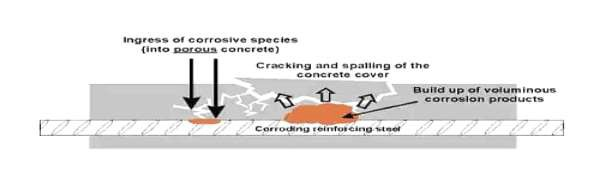

Below is a diagram showing the cracking and spalling of concrete cover.

Causes of Concrete Spalling

There are various reasons due to which spalling of concrete occurs;

- Corrosion of embedded steel reinforcement. Corroding steel hold more additional volume than the original, and it can extend up to ten times its initial volume, exerting force on the surrounding concrete.

- Insufficient thickness concrete cover to reinforcement

- Poor quality concrete cover to steel reinforcement

- Alkali-Silica Reactions Expansive effects.

- Improperly constructed joints often cause joint spalls, leading to joint spalling.

- Failure of bond in two-course construction because of shrinkage variation between top and base courses, drying the bonding grout before placing the top concrete course, etc.

- Exposure to fire.

- Freeze and thaw cycling.

In short, spalling can affect anything constructed of concrete – but we most often see it in conjunction with foundation failure due to foundation settlement or foundation heave (both of which are caused by expansive soil).

Essential Factors for the Protection of Steel Bars

One of the primary factors for corrosion safety includes;

- The thickness of the concrete cover protecting the reinforcing steel. As per the thumb rule, a concrete cover of one inch or double the diameter of the main bar is necessary to protect the steel bar.

- Ensuring that the concrete is adequately compacted during pouring.

- Placing concrete with the appropriate consistency and compaction of the wet concrete before it starts to harden.

Repair of Concrete Spalling

Concrete spalling differs depending on the concrete structure’s damage intensity, type and location. Armorsil West Africa recommends ARMORPATCH 100 and ARMOR LATEX OR ARMORSUPERLATEX for the repair of concrete spalling as follows:

Cleaning of Spalled Concrete Area

- Firstly, clean the area that needs repairing from dirt to avoid bond breaker agents. In case heavy dirt and stains may require a pressure washer to clean the surface properly.

- Remove the broken and loose concrete via chisel and hammer from the area. In some cases, grinding or shot blasting may also require for preparing the surface properly.

For finding any possible deterioration, tapping of the nearby area is advisable. Deteriorate concrete produces a hollow sound, and it should be removed to avoid future concrete repair.

- Finally, is the application of the ARMORPATCH 100 and ARMORLATEX or ARMORSUPERLATEX.