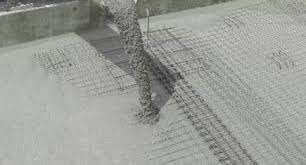

Workability of concrete is a broad and subjective term describing how easily freshly mixed concrete can be mixed, placed, integrated and finished with minimal loss of homogeneity. It is determined by how fluidic the mix is (i.e the cement to water ratio). It is a property that directly impacts strength, quality, appearance, and even the cost of labor for placement and finishing operations.

MEASUREMENT OF WORKABILITY

It is measured in terms of the ease with which it can be mixed, transported to construction site, placed in forms and compacted.

FACTORS AFFECTING WORKABILITY

The various factors affecting the workability of concrete are materials such as water content, cement content, aggregate properties, mix design ratio and use of admixtures. We are going to look at the various factors one at a time

- WATER CONTENT: The higher the water content per cubic meter of concrete, the higher the fluidity of the concrete. This implies that concrete workability can be increased if certain amount of excess water is added at the site. However, it should be noted that increasing the water content of concrete will have effect in the strength of the concrete, and this can be balanced if a certain amount of cement is also added to enable the cement ratio remains constant.

- CEMENT CONTENT: Cement content is also another factor that affects the workability of concrete. The larger the quantity of cement, the more will be the paste available to coat the surface of aggregates and fill the voids between them. This helps to reduce friction between aggregates and smooth movement of aggregates during mixing, transporting, placing and compacting of concrete is achieved.

- GRADING OF AGGREGATE: This factor has a maximum influence on the workability of concrete. A well-graded aggregate tends to fill up voids, thus when the total voids are less, excess paste will be available to give a better lubricating effect.

- SHAPES OF AGGREGATES: The shape of aggregates has a considerable influence on workability of concrete. The rounded shape aggregates have better workability, less surface area, and less voids than the elongated or flaky aggregates.

- USE OF ADMIXTURE: Admixtures is a material other than water, aggregates and cement used as an ingredient of concrete and added to the batch immediately before or during mixing. It is used where a high degree of workability and when high ambient temperatures cause rapid slump loss. Admixtures facilitates the production of high-quality concrete and also helps to minimize segregation and bleeding; thus, aids pumping of concrete.

At Armorsil West Africa, with the help of our concrete admixtures, reduction in water content is achieved at the same time increasing the strength and workability of concrete. Our various range of Hydroplast series gives that increased strength and workability that is needed. They include;

- Hydroplast 200D

- Hydroplast 240GP

- Hydroplast 260GR

- Hydroplast 280GR

- Hydroplast 460GP

- Hydroplast 520GR

In conclusion, it should be noted that in concrete mixing, each and every process and materials involved affects the workability of concrete.